Welcome to Henan Fote machinery machine limited company official website!sales@sinofote.com

Home > Stone crushing machine > Jaw crushers

Processing capacity: 12-1000 t/h

Discharge opening: 3-60 mm

Feeding size: 35-300 mm

Applied material: barite, marble, talcum, calcite, dolomite, fluorite, kaoline, coal, gypsum.

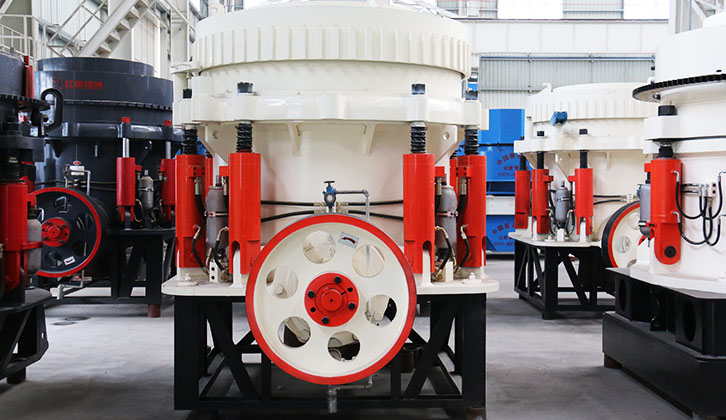

Chat LineGet a QuoteCone crusher is suitable for crushing all types of ores and rocks with compression strength no more than 300 Mpa. The advantages are: high efficiency, reliable structure, easy-to-adjust and economical. It is widely used in the works of mine, smelting, building material, road, railway, irrigation , chemical industry ,etc.

The crushing chamber is decided by the purpose of ore, the standard model is suitable for medium crushing, the medium model is suitable for fine crushing and the short head model is suitable for fine crushing.

This cone crusher is made up of main frame, transmission shaft, eccentric bushing, bowl一shaped bearing, crushing cone, adjusting device, adjusting sleeve, spring, elastic coupling, lubricating station, hydraulic station and electric appliance.

1. The sealing and anti-dust device is to protect the lubrication grease from becoming dirty and protect the main spare parts from dust, thus avoiding abnormal abrasion.

2. The spring is used for protecting the crusher from being damaged when the materials that cannot be crushed go into the crusher.

3.The main frame, using high strength alloy steel casting, precision forging processing, durable, suitable for crushing hard material, light weight;

When cone crusher works, the electromotor drives the eccentric bushing to rotate through the transmission shaft and a pair of bevel gears. The crushing cone will be forced by the eccentric bushing to revolve, so that the crushing wall of cone crusher gets close to and then gets away from the surface of the rolling mortar wall, and the ores inside the crushing chamber will be constantly impacted, squeezed and bent to be crushed.

| Specification | Model | Diameter of large end of crushing cone (mm) |

Max.feeding size(mm) |

Width of discharge opening (mm) |

Processing capacity (t/h) |

Motor power (kw) |

Total weight (t) |

Dimensions (L×W×H) (mm) |

| Φ600 | PYB600 | 600 | 65 | 12-25 | 40 | 8P 30 | 5 | 2234×1370×1675 |

| PYD600 | 35 | 3-13 | 12-23 | 5.5 | 2234×1370×1675 | |||

| Φ900 | PYB900 | 900 | 115 | 15-50 | 50-90 | 8P 55 | 11.2 | 2692×1640×2350 |

| PYZ900 | 60 | 5-20 | 20-65 | 11.2 | 2692×1640×2350 | |||

| PYD900 | 50 | 3-13 | 15-50 | 11.3 | 2692×1640×2350 | |||

| Φ1200 | PYB1200 | 1200 | 145 | 20-50 | 110-168 | 8P 110 | 24.7 | 2790×1878×2844 |

| PYZ1200 | 100 | 8-25 | 42-135 | 25 | 2790×1878×2844 | |||

| PYD1200 | 50 | 3-15 | 18-105 | 25.3 | 2790×1878×2844 | |||

| Φ1750 | PYB1750 | 1750 | 215 | 25-50 | 180-360 | 8P 160 | 50.3 | 3910×2894×3809 |

| PYZ1750 | 185 | 10-30 | 80-210 | 50.3 | 3910×2894×3809 | |||

| PYD1750 | 85 | 5-13 | 60-180 | 50.2 | 3910×2894×3809 | |||

| Φ2200 | PYB2200 | 2200 | 300 | 30-60 | 420-700 | 8P 280-260 | 80 | 4622×3302×4470 |

| PYZ2200 | 230 | 10-30 | 130-410 | 80 | 4622×3302×4470 | |||

| PYD2200 | 100 | 5-15 | 80-200 | 81.4 | 4622×3302×4470 |

Online Message

If you have any problems or questions about our products or need our support and assistance, please feel free to write us, we will reply to you within 24 hours, and never reveal your information to the third party. Thank you!