Welcome to Henan Fote machinery machine limited company official website!sales@sinofote.com

Home > Stone crushing machine > Jaw crushers

Full automatic control system

low operating cost

Secondary, Tertiary and quaternary crushing process.

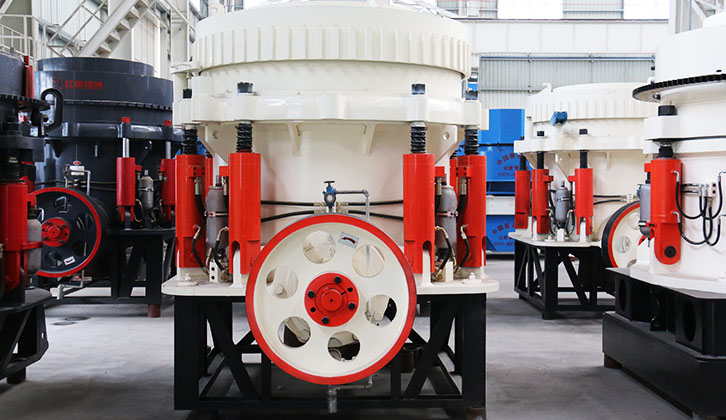

Chat LineGet a QuoteCS series single cylinder hydraulic cone crushers adopt the world’s most advanced crushing tenology. the new structure integrating meanics, hydraulics, intelligent-control and other tenologies, together with optimized interparticle crushing cavity and full-intelligent automatic control system,endows the CS with excellent performance that traditional cone crushers cannot compare with :various crushing cavities, high crushing efficiency, low operation Cost, easy maintenance and cube sized product. CS series cone crusher can be widely applied to secondary, tertiary, and quaternary crushing process.

1 .Unique Main Shaft Strut and Sliding Bearing Design

For main shaft, strut o n both ends design stabilizes the stress and improves the equipment's bearing capacity and reliability. Special oil wedge design for sliding bearing can avoids direct functional contact of the shaft and bearing. In addition,special bearing materials bring greater compressive capacity, excellent ability to resist adhesive and amazing adaptability in poor working conditions.

2. Enhanced Frame

The whole frame structure and the layout of the strengthening rib are Optimized. Besides, the upper frame adopts unique star jib structure.

3. Transmission system

By using spiral bevel gear, the transmission system ensures that the transmission process is high efficient, reliable and stable with low noise and long lifespan.The transmission shaft adopts rolling bearing and unique bearing material to promise a greater compressive capacity.

4.Disarging Adjustment & Overload Protection

By adopting a structure that combines main shaft floating and lift control by hydraulic pressure, the disarging adjustment and overload protection are integrated and can be aieved meanwhile. The optimized structure design simplifies the crusher structure while ensuring the performance. Compared with other types of cone crushers, the series need no extra additional complicated

5. Optimized Hydraulic Lubrication Station

Integrated design of hydraulic station and lubrication station saves the installation space.

1 .Large Capacity & high Efficiency

The high performance of CS series cone crushers depends on the perfect match between different components. With perfect integration of eccentricity, cavity and equipment motion parameters, has aceived stronger crushing force, higher speed and the best stroke, the optimized strength design and high quality components endow CS with greater compressive capacity. The

capacity of is 20%一30% higher than that of spring cone crusher with the movable cones of same diameter.

2. Interparticle crushing & cube sized product

Interparticle crushing principle with high pendulum frequency of movable cone increases the capacity and improves particle shape of the product significantly, making the proportion of superior particle shape in the finished products increase significantly and particle shape in the finished products increase significantly and particle shape is more regular.

3. Multiple cavities with the best stroke to meet various process requirements

CS(H) can be applied to both coarse crushing and fine crushing. For a certain type of CS(H) cone crusher, there are various cavities to choose, and the eccentric distance can be adjusted by CS(H) cone crusher anaing the eccentric sleeve. Different cavities and eccentric distances can be equipped according to different production processes so that the equipment value can be maximized. CS(H) cone crushers can provide excellent performance in secondary crushing, and it is a also the best CS(H) cone crusher choice for tertiary and quaternary crushing. As a secondary crusher, the capacity of production line can be greatly improved by maximizing the primary crusher`s closed side setting.

4. Long lifespan lining plate

The design concept of constant crushing cavity means that the cavity shape remains the same when lining plate is worn, while can ensure high crushing efficiency thus aieving synronized wear of lining plate. Avoiding local damage of lining plate, and reaing a consistent wear rate, extending the cycle of lining plate.

5 .Full automatic control system

Full automatic control system adopts PLC+touch screen control mode, real-time monitors temperature, pressure, electrical Flow and other core parameters, and automatic control to ensure safe operation of equipment

6. Simple structure & low operating cost

All the maintenance work can be completed after removing the upper frame, while CS(H) cone crusher not only makes the device inspection and maintenance easier but also reduces the maintenance cost.

Dust and other unwanted particles can be prevented from entering the cavity by ensuring that the cavity's inner pressure is always higher than its external pressure. Thus, the damage of bearings and maintenance work is reduced. The life cycle of lubricatingoil and device are extended.

In addition, the compact design of main maine saves installation space, while CS(H) cone crusher making the device easy to move.

| Model | Cavities | Feeding size(mm) | Maximum Feeding size(mm) | Minimum Discharging Size(mm) | Capacity(t/h) | Power(kw) |

| HPM200 | C1 | 185 | 145 | 22 | 160~250 | 160 |

| C2 | 125 | 100 | 18 | 145~250 | ||

| C3 | 95 | 75 | 14 | 120~250 | ||

| F1 | 76 | 60 | 12 | 108~210 | ||

| F2 | 54 | 45 | 10 | 81~210 | ||

| HPM300 | C1 | 235 | 190 | 26 | 230~445 | 220 |

| C2 | 211 | 170 | 20 | 200~445 | ||

| C3 | 150 | 120 | 16 | 180~445 | ||

| C4 | 107 | 85 | 14 | 160~220 | ||

| F1 | 53 | 40 | 12 | 140~220 | ||

| HPM400 | C1 | 299 | 240 | 35 | 270~630 | 315 |

| C2 | 252 | 200 | 25 | 252~630 | ||

| C3 | 198 | 160 | 25 | 243~630 | ||

| C4 | 111 | 90 | 18 | 210~630 | ||

| F1 | 92 | 75 | 15 | 162~370 | ||

| F2 | 52 | 40 | 13 | 126~370 | ||

| HPM500 | C1 | 335 | 270 | 38 | 365~790 | 400 |

| C2 | 286 | 230 | 30 | 328~790 | ||

| C3 | 204 | 165 | 22 | 280~790 | ||

| F1 | 133 | 105 | 20 | 202~450 | ||

| F2 | 95 | 75 | 16 | 175~450 | ||

| F3 | 52 | 42 | 8 | 158~450 | ||

| HPM650 | C1 | 328 | 262 | 30 | 386~790 | 500 |

| C2 | 279 | 225 | 25 | 348~790 | ||

| C3 | 196 | 175 | 20 | 300~790 | ||

| F1 | 106 | 85 | 13 | 280~530 | ||

| F2 | 52 | 42 | 9 | 220~530 | ||

| HPM800 | C1 | 353 | 280 | 38 | 616~1100 | 630 |

| C2 | 297 | 240 | 38 | 522~1100 | ||

| C3 | 267 | 214 | 25 | 495~1100 | ||

| C4 | 219 | 175 | 22 | 380~1100 | ||

| F1 | 155 | 125 | 20 | 328~730 | ||

| F2 | 92 | 75 | 16 | 270~730 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

Online Message

If you have any problems or questions about our products or need our support and assistance, please feel free to write us, we will reply to you within 24 hours, and never reveal your information to the third party. Thank you!